ADELPHI, Md. -- Prototype flexible screens will soon show the way for future device interactions and capabilities as the Department of Defense announced it will continue investing in this technology.

The NextFlex Manufacturing Innovation Institute entered its second cooperative agreement with the U.S. Air Force Research Laboratory. Government program management will be the responsibility of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory.

As a part of this agreement, NextFlex will aid DOD’s mission to promote U.S. leadership in flexible hybrid electronics through the commercialization of prototype technologies developed by the Army.

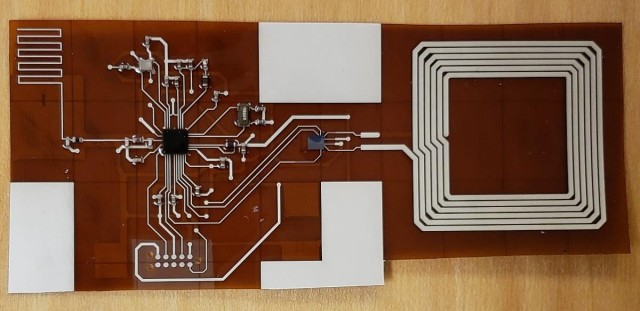

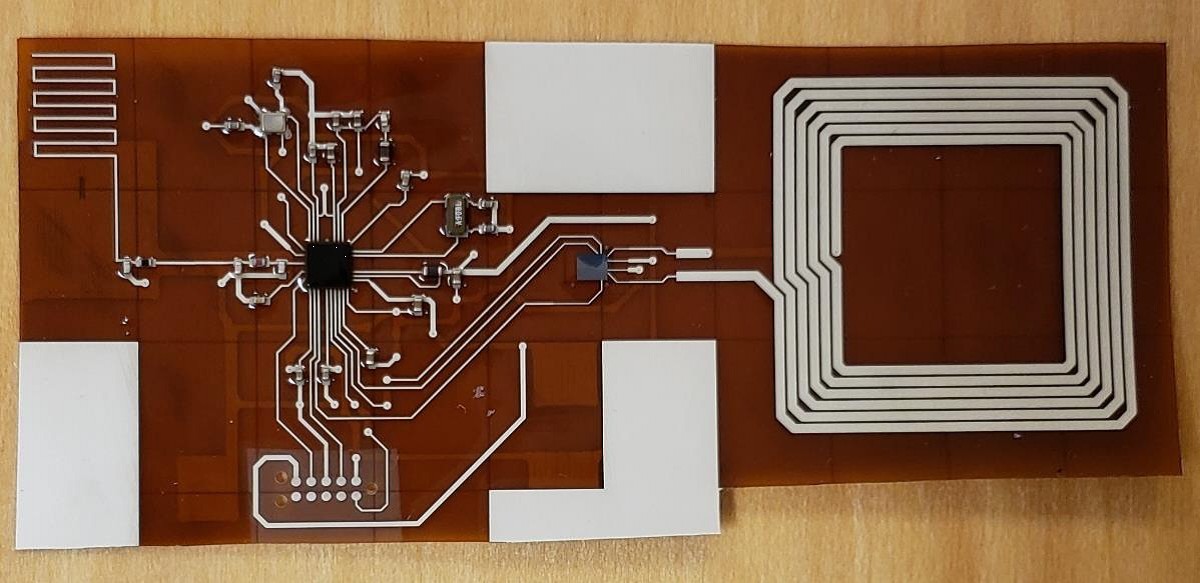

“Flexible hybrid electronics is a new way to manufacture electronics that brings together digital additive manufacturing with traditional electronic components,” said Dr. Eric Forsythe, an Army physicist with the lab and the government program manager for NextFlex.”

Examples of these technologies include wearable devices that monitor health as well as communication and sensor platforms that enable Soldier authentication to a network led by the Command, Control, Communication, Computers, Cyber, Intelligence, Surveillance and Reconnaissance Center, known as C5ISR, has been leading a program to demonstrate Soldier network authentication devices for Soldier Lethality. They may also help monitor the structural health of roads, bridges and building and even allow researchers to gain a substantial foothold in soft robotics.

“These manufacturing capabilities directly align with ARL’s Science of Additive manufacturing Essential Research Program, demonstrating the power of collaborative research,” Forsythe said.

NextFlex launched in 2015 through a $171 million cooperative agreement between the Department of Defense and the NextFlex institute. From 2015 to 2020, the initial partnership yielded more than 50 agency-funded projects that leverage more than 60 core funded flexible hybrid electronics manufacturing projects, many of which directly supports U.S. Army modernization priorities.

The second cooperative agreement signed between NextFlex and the U.S. Air Force Research Laboratory serves to further strengthen the public-private partnership and establish a U.S. manufacturing base to support both DOD and commercial applications. The official arrangement will span from 2020 to 2026 with a total of $154 million of funding provided by the Office of the Secretary of Defense ManTech Office.

The lab will primarily function as a facilitator in this agreement and task additionally with the responsibility to oversee the transition of Army technology into the private sector.

“The Army Research Laboratory supports various activities within the NextFlex institute, which out of a portion of its funding, supports core projects,” Forsythe said. “The lab has been actively supporting the technical development under the Science for Additive Manufacturing for Munition Essential Research Program. We have also utilized the agreement where funding from the laboratory has developed projects that then get technology back to the lab to support the Army Modernization Priorities.”

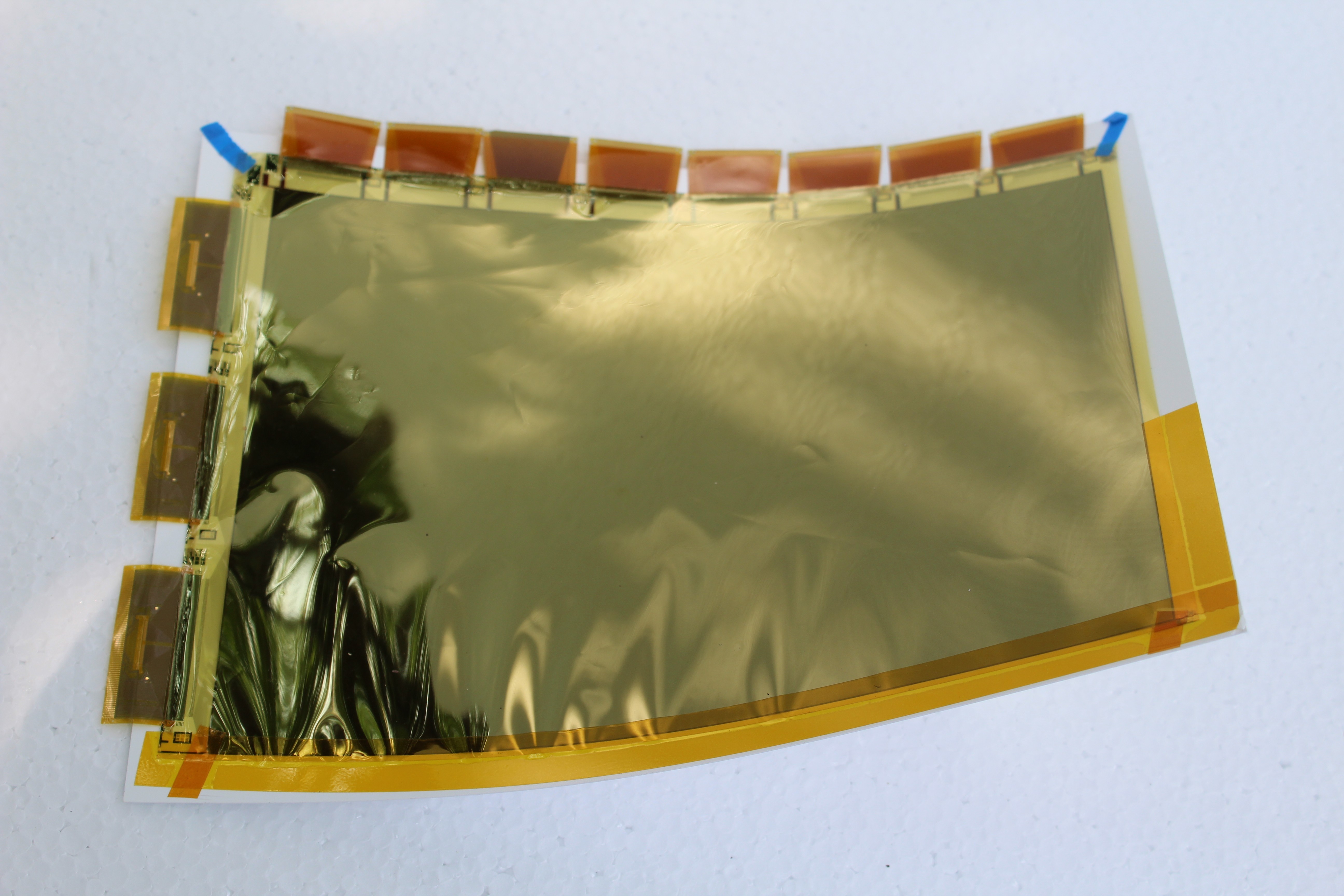

Examples of such projects include the flexible screen X-ray imager, a lightweight, portable digital detector array for inspection that allows technicians to scan and examine the contents of a suspected improvised explosive devices without touching them. This project highlights key partnerships with Defense Threat Reduction Agency, CCDC-ARL, AFRL, and NextFlex with the industry and academic partners.

The flexible X-ray imager, developed by Army researchers at the laboratory and at the Army’s Flexible Display Center at Arizona State University, can withstand extreme battlefield conditions that commercial off-the-shelf systems often cannot handle. In addition, the flexible X-ray imagers only weigh a few pounds, whereas conventional x-ray panels are typically too heavy for warfighters to carry onto the field with ease.

Once researchers finished the prototype, the Army transitioned the flexible X-ray imager through NextFlex to manufacture and commercialize a fully flexible version of the product. Under the second cooperative agreement, the DOD X-ray imager devices will complete its transition to domestic manufacturing through the NextFlex Flexible Hybrid Electronic manufacturing ecosystem.

With the flexible X-ray imager, the goal is to bring the pieces together to get the technology into the hands of future Soldiers, Forsythe said.

“We want to make sure that the technology, the funding and the manufacturer are all aligned to support the end customer,” he said.

Another notable example of a flexible hybrid electronic system currently under transition in this agreement is a Soldier token authentication device that warfighters would wear to authenticate themselves to the Army network. This project, led by the CCDC- C5ISR Center, directly impacts the Soldier Lethality and Network Army modernization priorities.

Both the flexible X-ray imager and the authentication device represent only two out more than 60 DOD projects currently secured through the NextFlex cooperative agreement.

“The core funding and other OSD money supports the underlying manufacturing capability of the Army,” Forsythe said. “We want to leverage the industrial base and the manufacturing ecosystem that we built to push this kind of technology forward.”

CCDC Army Research Laboratory is an element of the U.S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL discovers, innovates and transitions science and technology to ensure dominant strategic land power. Through collaboration across the command’s core technical competencies, CCDC leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more lethal to win the nation’s wars and come home safely. CCDC is a major subordinate command of the U.S. Army Futures Command.

Social Sharing